[ad_1]

One facet during which most Indian households excel is the artwork of stockpiling objects for future use. Our storerooms usually home peculiar objects like outdated cardboard packing containers and considerable thermocol sheets.

Whether or not it’s for events, faculty initiatives, or packaging wants, thermocol regularly assumes the position of an important visitor. Its robustness, widespread availability, and light-weight nature make it appropriate for varied functions, contributing to its recognition.

Nevertheless, amidst its seemingly versatile functions, we are inclined to overlook its environmental affect. Whereas a lot consideration is given to the detrimental results of plastic on the planet, there’s a less-discussed wrongdoer — polystyrene. As thermocol consists of polystyrene, it turns into non-biodegradable and, when uncovered to daylight, produces dangerous air pollution.

The thermocol utilised in households and the expansive packaging business usually finally ends up filling landfills, finally discovering its technique to the ocean. Analysis signifies that burning thermocol, a follow prevalent in lots of households, releases not solely Carbon Monoxide but additionally Styrene and a wide range of different poisonous chemical compounds, resulting in a myriad of eye and lung infections.

Regardless of quite a few research highlighting the opposed results of thermocol, its widespread utilization continues to escalate. This raises a pivotal query: is there a relatively efficient various for the packaging business?

A 29-year-old engineer Chaitanya Dubey from Kanpur, Uttar Pradesh, might maintain the answer to this concern. This younger entrepreneur has efficiently created a biodegradable various to conventional thermocol utilizing mushroom mycelium and agricultural waste.

“As soon as its meant objective is fulfilled, simply crush it and combine it into your vegetation — it can function a pure fertiliser for them,” he explains to The Higher India.

Chaitanya’s journey started nearly 4 years in the past when he had simply graduated from school and was exploring new concepts to pursue. Let’s check out how this biodegradable resolution got here to be.

Bringing a sustainable various

Born and raised in Kanpur, Chaitanya grew up in a business-oriented household. “Whereas my father was a businessman, I by no means actually thought I might be one. Like most households, my dad and mom needed me to pursue engineering and safe a job,” he displays.

The predetermined path appeared affordable, and Chaitanya pursued his engineering diploma in Bengaluru. “After finishing engineering, the following step is usually to work or pursue an MBA. That was my plan too. I began working at an organization in Bengaluru whereas considering the concept of getting an MBA,” he shares.

Nevertheless, his plans took an surprising flip when he enrolled in a small enterprise course in Solan. “It was a quick course that, in some ways, altered my trajectory and led me to the place I’m in the present day. The course opened up varied profession prospects for me, and I may envision myself as an entrepreneur. It was throughout this course that I used to be launched to mushroom farming and its potential for producing important income,” he explains.

Mushroom farming marked the preliminary step that finally led Chaitanya to his modern breakthrough. “I initiated a small enterprise the place I cultivated each medicinal and business mushrooms. Whereas it was progressing properly, I aspired to do extra,” he recollects.

This want prompted Chaitanya to delve into researching the various makes use of of various elements of mushrooms. Throughout this exploration, he found the rising idea of making leather-based from mushrooms.

“Though it was primarily a circulating idea on the time, it steered me in the direction of questioning what else might be crafted utilizing mushrooms,” he displays.

To additional his analysis, he additionally reached out to IIT-Kanpur. “It was a gradual transition and we nonetheless develop and promote mushrooms. It was after months of analysis and growth that I used to be capable of make it,” he says.

In 2019, he included his firm underneath the identify Kinoko Biotech — an agri-tech firm that makes biomaterials out of mushrooms.

Sturdy, light-weight and planet-friendly

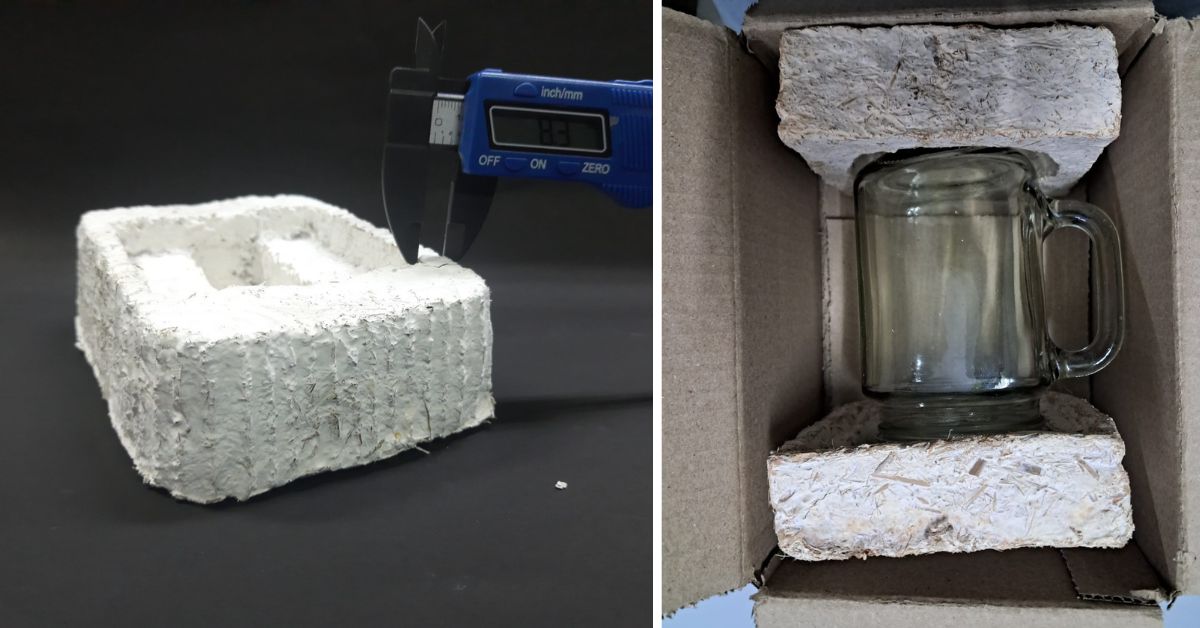

The thermocol is light-weight, sturdy and has the identical really feel because the polystyrene. “When it comes to energy, it compares favourably to high-density thermocol; nonetheless, weight-wise, it leans a bit on the heavier aspect,” he informs.

Discussing the weather used to create the eco-friendly various, he explains, “Mycelium, or the roots of the mushroom, serves as a pure adhesive. Moreover, we utilise a mix of agricultural waste and pure fibres, contributing to the sturdiness and longevity of the thermocol. The inherent properties of mushrooms make for a sturdy materials.”

He continues, “Since these are technically made out of roots of the mushroom, they turn out to be a byproduct of mushroom and a subcategory. Manufactured from pure supplies, the thermocol begins to decompose in about 60 to 90 days. Apart from throwing it away, one can really use it as a nourisher and pure fertiliser for vegetation.”

The thermocol takes about 5 to seven days to be made. “In relation to thermocol, there exists a variety of types. Our product falls on the marginally greater value spectrum in comparison with low-density thermocol however stays extra reasonably priced than high-density thermocol,” he says.

“To place it into perspective, our pricing falls within the mid-range, round Rs 20 to Rs 25 for 100g of packaging. As compared, low-density thermocol sometimes ranges from Rs 15 to Rs 20, whereas high-density thermocol can differ broadly, reaching anyplace from Rs 30 to Rs 100 or extra,” he says.

The product is presently accessible for packaging companies, however Chaitanya has bold plans to develop manufacturing and make it accessible for most people as properly.

“We’re additionally within the strategy of growing a cloth utilizing mushrooms to create idols. Many alternate options to POP (Plaster of Paris) are dangerous to the surroundings. Presently, our plant capability permits for the manufacturing of 200 items of thermocol a day, however as a part of our future plans, we intention to extend this to 1,000 items per day,” he explains.

Being a newcomer available in the market, Chaitanya is navigating the intricacies of provide chain administration and persuading companies to make this eco-friendly change.

“Whereas most individuals have some consciousness of the environmental affect of polystyrene thermocol, there aren’t many substitutes accessible available in the market. With my inexperienced innovation, I hope to supply them with another and a chance to contribute positively to the surroundings,” he expresses.

(Edited by Padmashree Pande)

[ad_2]